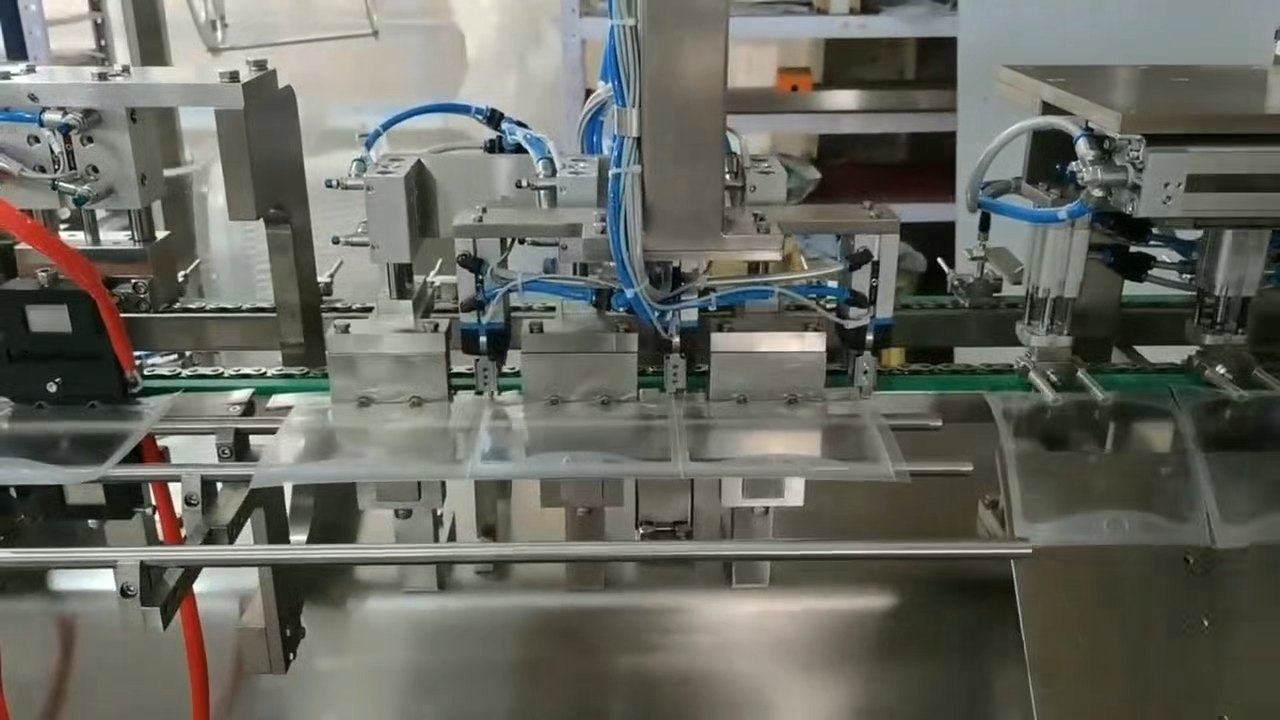

Non-PVC IV Bag Making Machine

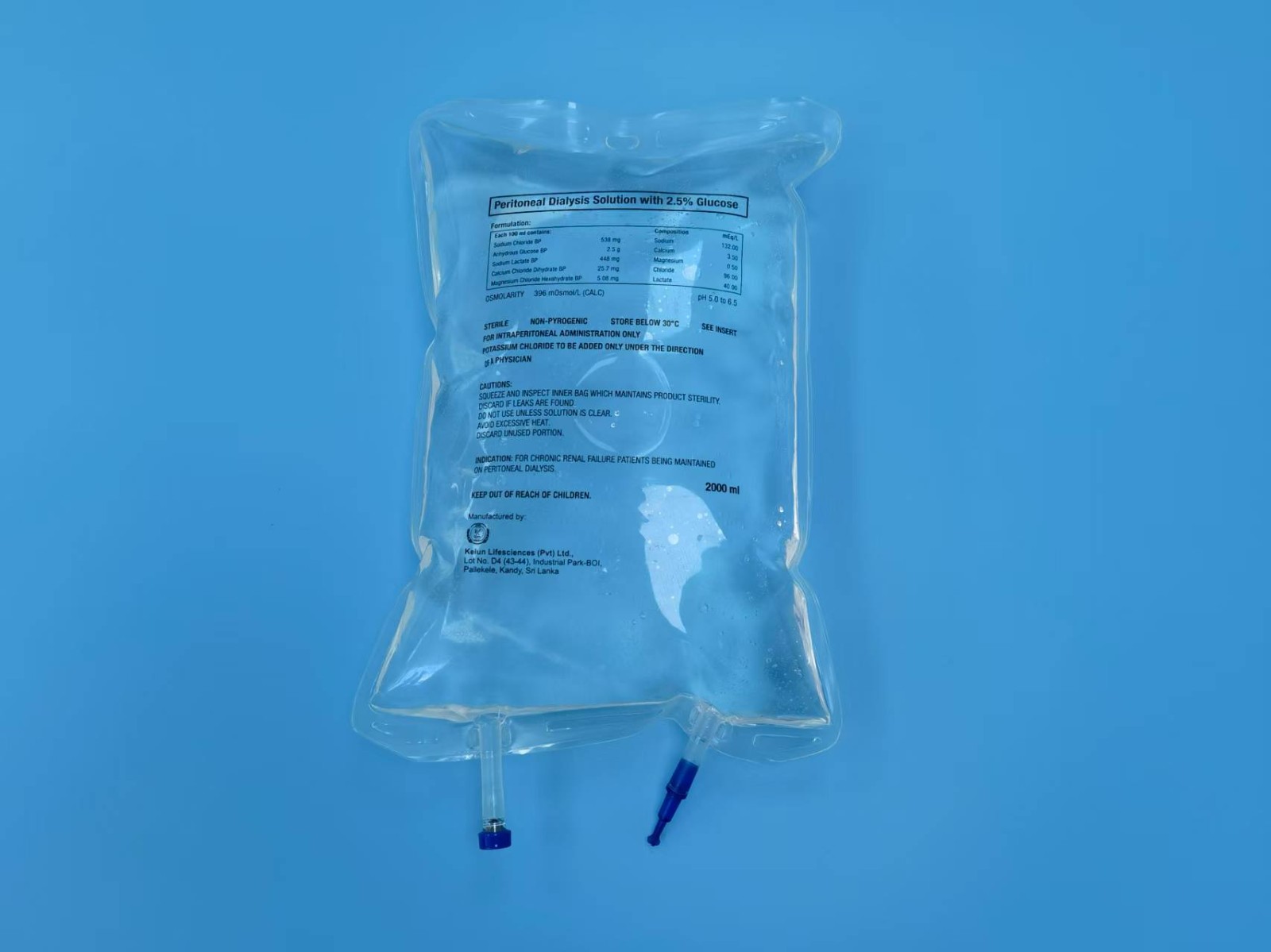

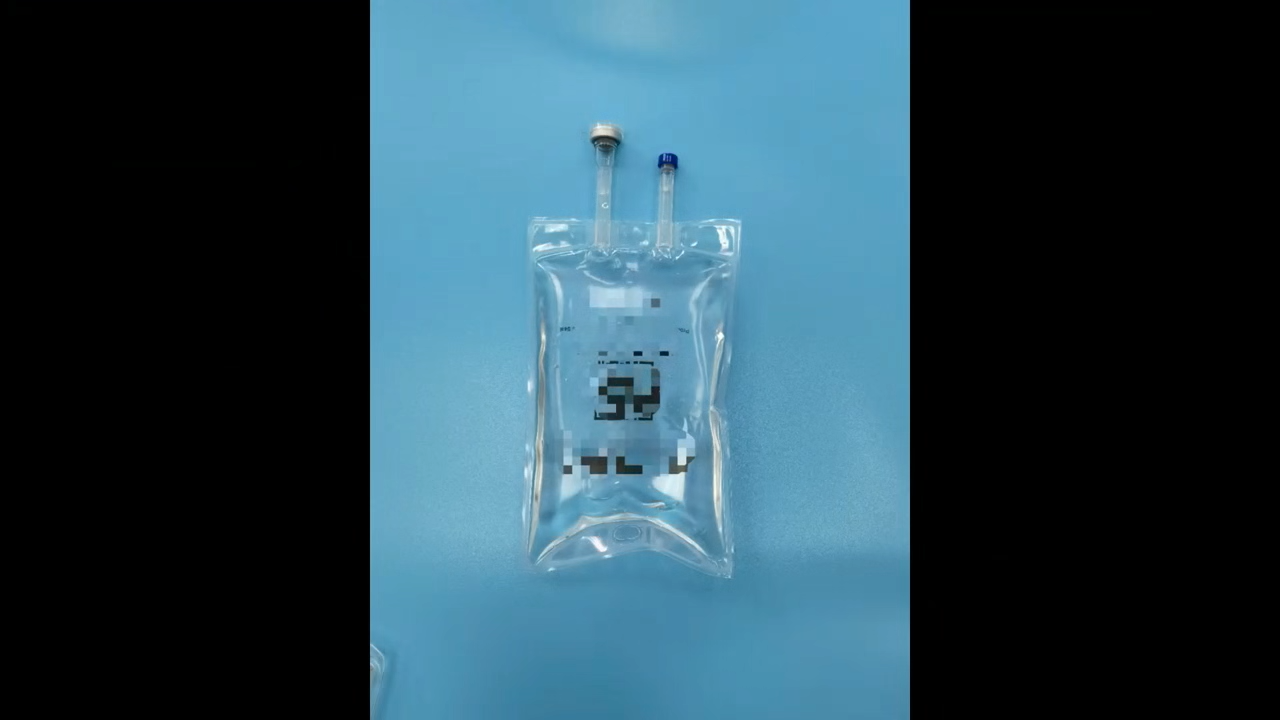

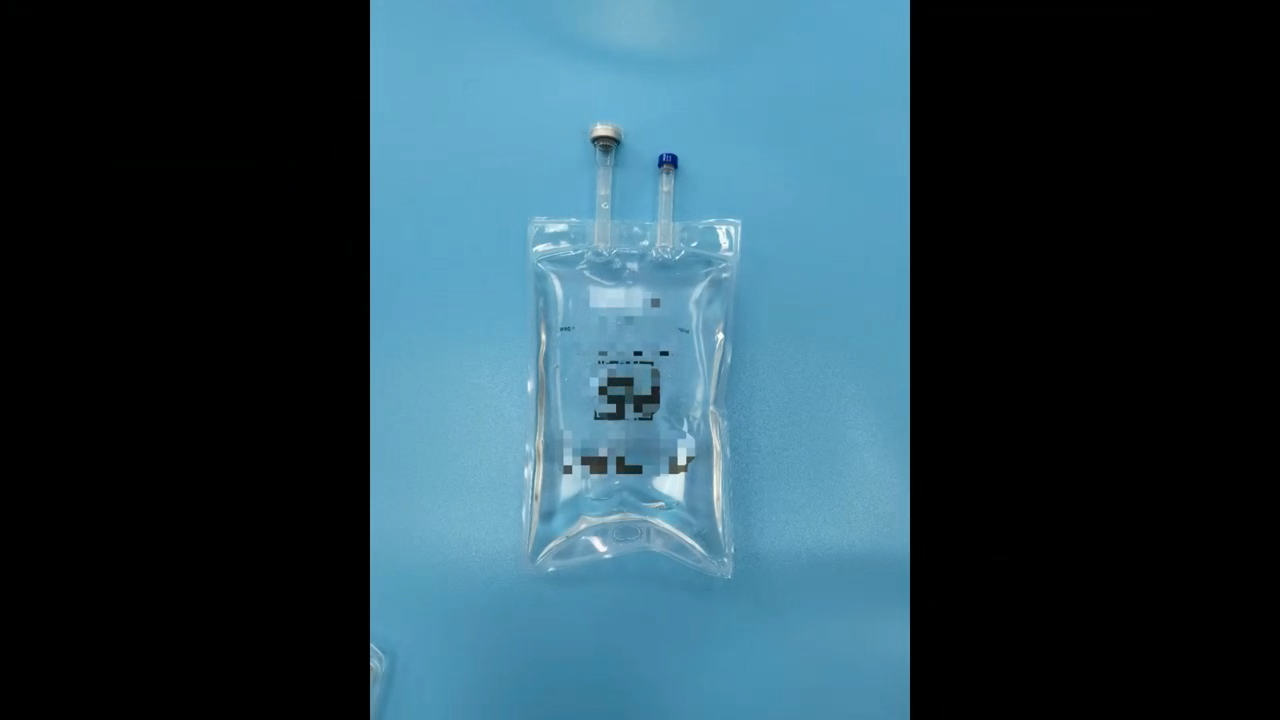

This is a fully automatic Non-PVC IV bag making machine with high precision and easy operation, it cam make 50ml, 100ml, 200ml, 250ml, 500ml, 1000ml and until 10 liter IV bags with single tube or double tubes, it can also make double chamber bag, also with peelable welding.

设备名称 Equipment Name | 全自动非PVC软袋制袋机 Automatic non - PVC soft bag forming machine | ||||

设备型号 Equipment type | CSS2 | ||||

兼容规格 Compatible specification | 50ml, 100ml、150ml, 200ml、500ml、1000ml 2袋/组 2bags/group | ||||

设备功能 Equipment function | 产品信息印刷、制袋、输出 Product information printing, Forming and output | ||||

设备尺寸 Equipment size | L:4m;W:2.4m;H:2.1m | ||||

软袋规格影响设备尺寸,以合同签订时图纸为准。 Product specifications affect machine dimensions. Based on the contract drawings. | |||||

安装面积 Installation area | L:5.5m;W:4m;H:2.8m | ||||

考虑设备开门空间及层流安装,注:设备不含层流,需单独报价 Considering the equipment door space and laminar flow installation, note: the equipment does not include laminar flow, need to be quoted separately 软袋规格影响设备尺寸,以合同签订时图纸为准。 Product specifications affect machine dimensions. Based on the contract drawings. | |||||

设备产能 Equipment capacity | TYPE | 100ml | 250ml | 500ml | 1000ml |

Speed | ≥2500BPH | ≥2500BPH | ≥2200BPH | ≥1800BPH | |

测试条件:正确操作设备,合格原材料,压缩空气0.65Mpa。 Test conditions: Correct operation of equipment, qualified raw materials, compressed air 0.65Mpa 最终生产能力在确定袋膜材、软管后可以确定。因设备本身原因之外的因素造成的对生产速度的影响设备制造商不承担责任。 The final production capacity should be determined after the confirmation of film and tube. Any impact of production speed caused by external factors will be regarded as no responsibility to the machine manufacturer. | |||||

公共能源 Public energy | 电源Power: 3-phase 380V, 50HZ,MAX.8KW | ||||

压缩空气compressed air: 0.65-0.8Mpa, dry oil-free compressed air,1500L/min | |||||

冷却水:不需要 Cooling water: No need | |||||

设备重量 Equipment weight | 2T 整体吊装 Integral lifting | ||||

环境要求 Environment | 温度20-35℃,相对湿度45%-65% Temperature 20-35℃, relative humidity 45%-65% | ||||

运行噪音 Noise | 75dB 距离设备1m处测量。Measure 1m away from the machine | ||||

操作语言 Language | 中文/英文 Chinese/English | ||||

符合GMP相关要求 Comply with relevant GMP requirements |

通过CE认证 Pass CE certification |

符合输液袋生产的相关法律规范 In line with the relevant laws and regulations of I.V. bags. |

温控精度高,兼容不同供应商的合格膜材和软管 High temperature control precision, compatible with different suppliers of qualified film and hose |

模具加工精度高,易于调整,焊接稳定,降低漏液率 Mold processing precision is high, easy to adjust, welding stability, reduce leakage rate |

操作简单,运行稳定,合格率高 Simple operation, stable operation, high qualified rate |

结构紧凑,占地面积小,生产效率高 Compact structure, small footprint, high production efficiency |

加塞稳定,到位精确,保证封口合格率 Plug stability, accurate in place, to ensure the sealing pass rate |

原材料 Raw material | 名称 Name | 规格 Specifications |

膜 Membrane | 非PVC多层共挤输液膜 Non-PVC Multilayer Co-extrusion Composite Film | 内径6英尺,市场通用规格 Inner diameter 6 inch, general market specification |

接口 Interface | 非PVC多层共挤输液管 Non-PVC Multilayer Co-extrusion Composite Tube | 内径6.2±0.1mm,外径8.2±0.1mm Inner diameter 6.2±0.1mm, outer diameter 8.2±0.1mm |

色带 Ribbon | 软袋大输液转移热转印色带 Soft bag infusion liquid transfer thermal transfer ribbon | 内径3英尺,市场通过规格 Inner diameter 3 inch, general market specification |

生产原料质量影响设备生产速度和稳定性,因非设备本身原因之外的因素造成的影响,制造商不承担责任。 The quality of raw materials affects the production speed and stability of machines,Any impact of caused by external factors will be regarded as no responsibility to the machine manufacturer. | ||

本图供参考,客户袋型、规格影响设备布局,请以设计确认提供的图纸为准。

This diagram is for reference only,Layout is influenced by product specifications。

序号 Serial number | 项目 Project | 内容及说明 Content and description |

1 | 概述 overview | 兼容约定规格非PVC软袋产品的印刷、制袋、口管焊接、输出功能。 Compatible with the printing, Forming, pipe welding and output functions of non-PVC soft bag products of the agreed specifications. |

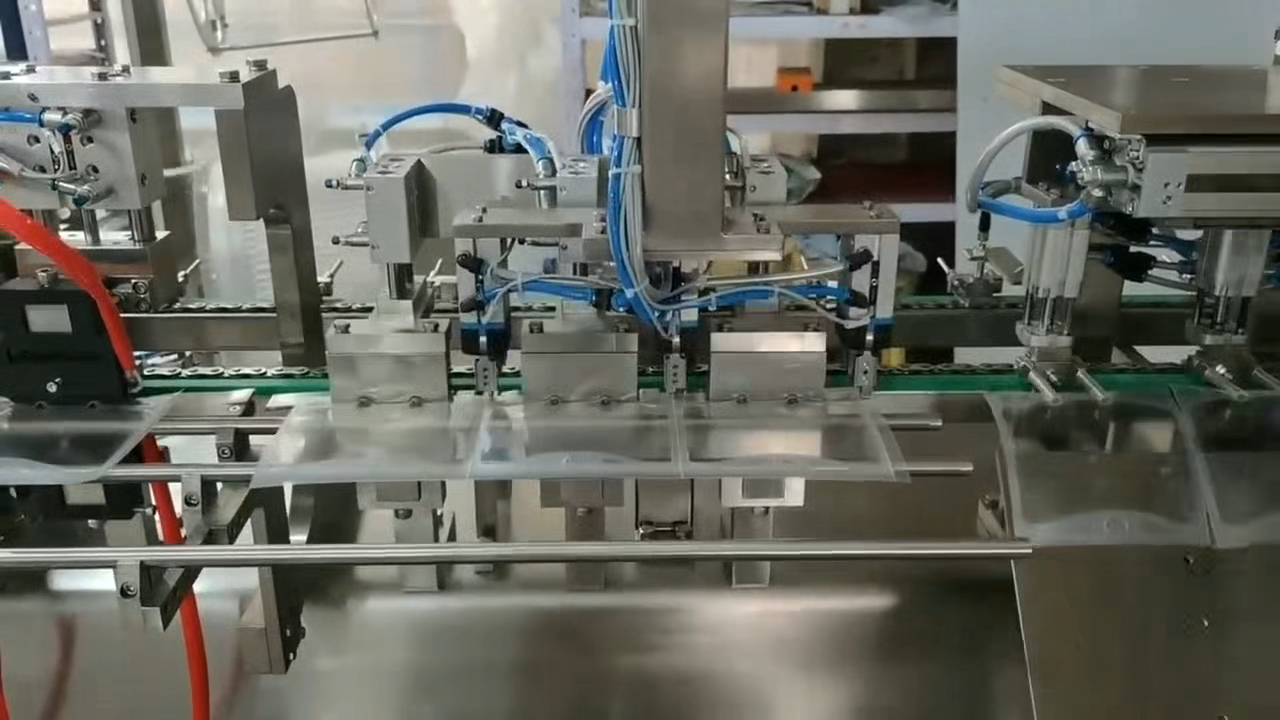

2 | 结构及工位 Structure and work station | 该设备设计为单轨线性系统,配有电机驱动膜材传送控制系统。 The machine is designed as a single-track linear system with a motor actuated film transfer control. In the machine. 根据其要求的能力,该机器配有一套工作工位。 According to its required capacity, the machine is either equipped with one working stations. 包括制袋工段,包括开卷、印刷、送膜、软管切割和供给、制袋、软管焊接、输出等工位。 Including unwinding station, printing station, film feeding station, hose cutting and supply station, forming station, hose welding station and output stations. |

3 | 设备材质 Equipment material | 设备框架及主要结构件均由304不锈钢制成; Equipment frame and main structural parts are made of 304 stainless steel; 模具由优质模具钢制成并做表面处理; The mold is made of high quality die steel and surface treatment;防护门为有机玻璃制成。 The protective door is made of plexiglass. 外购件材质以其本身说明书中的相关声明为准。 The material of the purchased parts shall be subject to the relevant statement in its own instruction manual. |

4 | 软件 Software | 通过触摸屏控制并监控整机运行; Control and monitor the operation of the machine through the touch screen; 触摸屏显示设备报警信息; Touch screen display device alarm information; 设备相关参数均可在触摸屏更改并保存; Device related parameters can be changed and saved on the touch screen; 具有数据保存功能,断电不丢失数据; With data saving function, power off without loss of data; 具有报警停机功能,错误将在触摸屏显示。 With alarm stop function, errors will be displayed on the touch screen. |

5 | 安全 Security | 设备可靠接地; Reliable grounding of equipment; 设备有一个急停开关; There is an emergency stop switch; 断电再次上电或解除急停后,设备需工人干预才能再次启动; After the power is switched on again or the emergency stop is lifted, the equipment can be started again only after the intervention of workers. 设备具有醒目安全标识; The equipment has an eye-catching safety identifier; 未尽事项详见说明书。 Please refer to the instructions for the matters not covered. |

6 | 开卷工位 Uncoiling station | 人工将膜卷安装在此工位; Manually install the film roll in this station; 通过气涨轴固定膜卷; The film roll is fixed by the inflatable shaft; 通过电机驱动膜卷释放和停止; Release and stop the film roll by motor drive; 膜将通过一个升降轴进入设备,保证膜输送平整; The film will enter the equipment through a lifting shaft to ensure smooth membrane transport; 膜断裂或用尽时,设备报警停机。 When the membrane is broken or exhausted, the equipment will alarm and stop. |

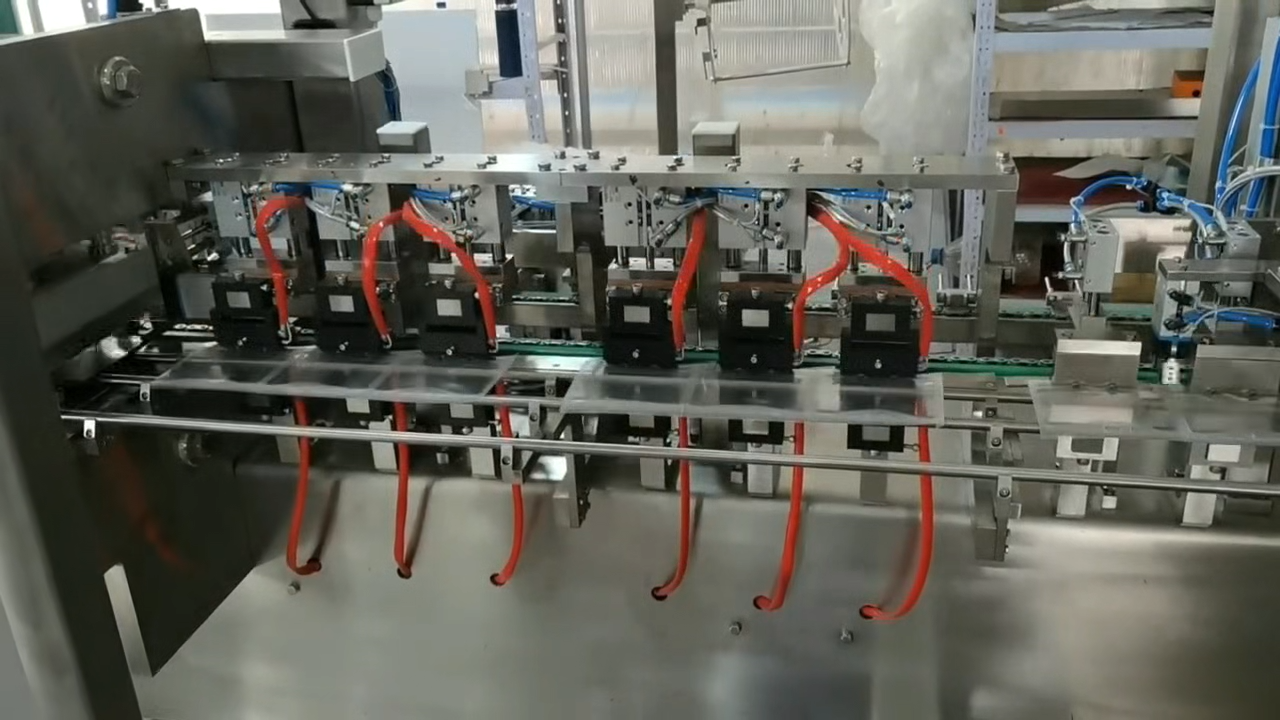

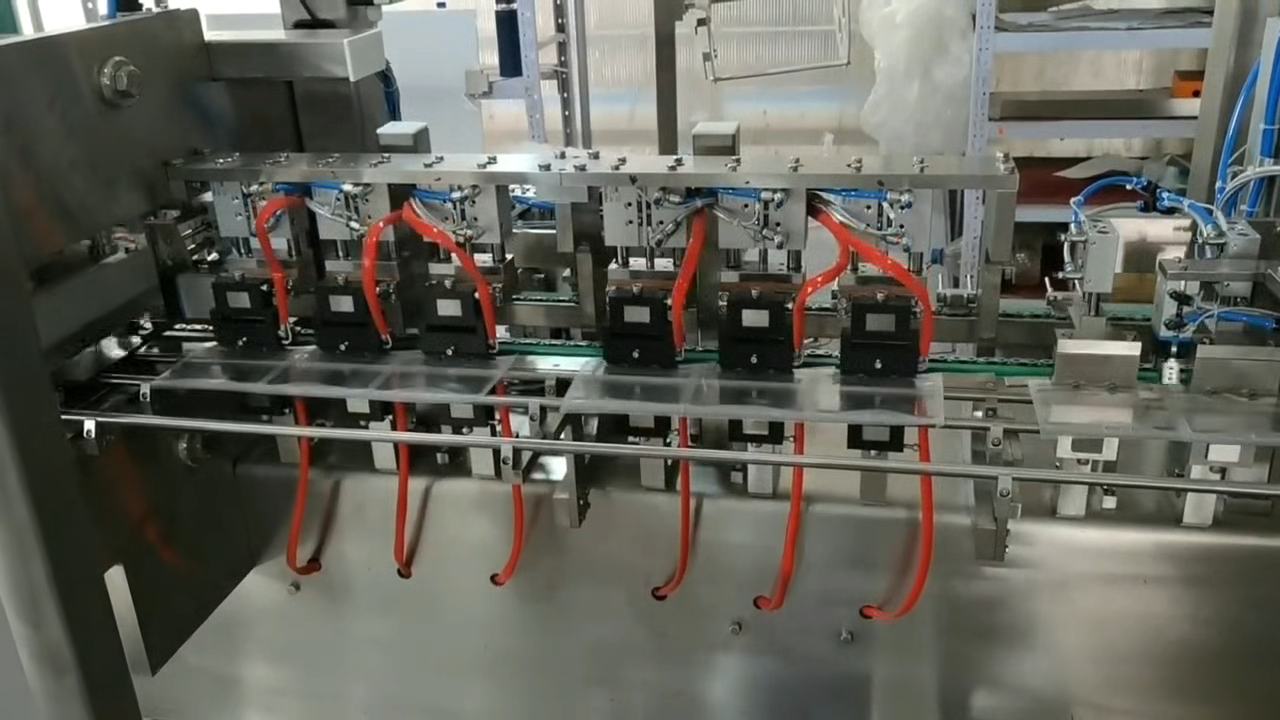

7 | 印刷工位 Printing station | 设备在此工位通过热烫印方式印刷产品信息; The equipment prints product information through hot stamping at this station; 随机配独立的批号、日期、有效期印刷模块,通过更换活字变更产品关键信息(随机提供一套完整的活字字头); The printing module with independent batch number, date and expiry date is provided randomly, and the key information of the product is changed by changing the movable type (a complete set of movable type header is provided randomly); 色带及回收卷都通过气涨轴固定,更换方便; The ribbon and the recovery roll are fixed by the balloon shaft, easy to replace; 色带通过电机释放和停止,释放长度通过编码器精确控制; The ribbon is released and stopped by the motor, and the release length is precisely controlled by the encoder; 印刷温度、时间,色带长度等参数可通过触摸屏设定。 Printing temperature, time, ribbon length and other parameters can be set through the touch screen. |

8 | 送膜工位 Film Feeding station | 此工位通过伺服系统输送膜材; This station transmits film material through servo system; 通过气动夹爪夹紧膜材; Through the pneumatic claw clamping film; 重复精度好,送膜均匀、稳定。 Good repetition accuracy, uniform and stable film feeding. |

9 | 制袋主传动 Bag Forming Main Drive | 设备设计为单轨线性系统, The machine is designed as a single-track linear system, 采用伺服驱动,保证良好的稳定性。 Servo drive is adopted to ensure good stability. |

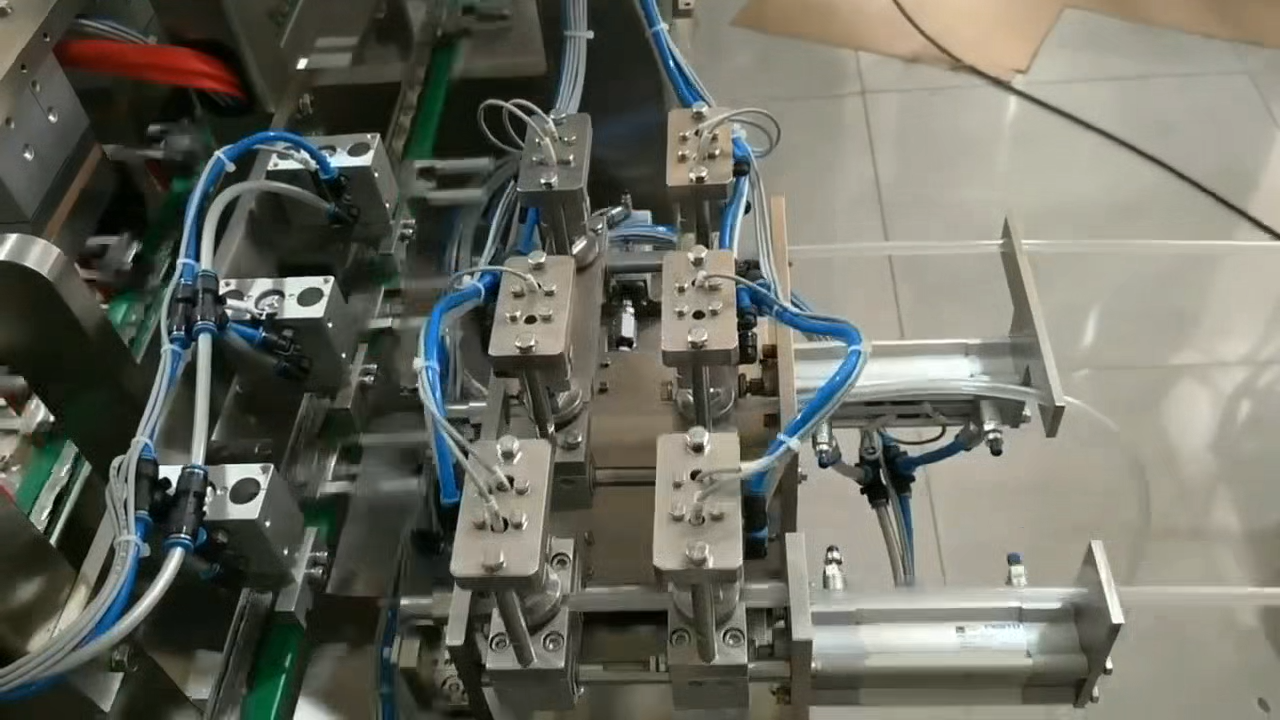

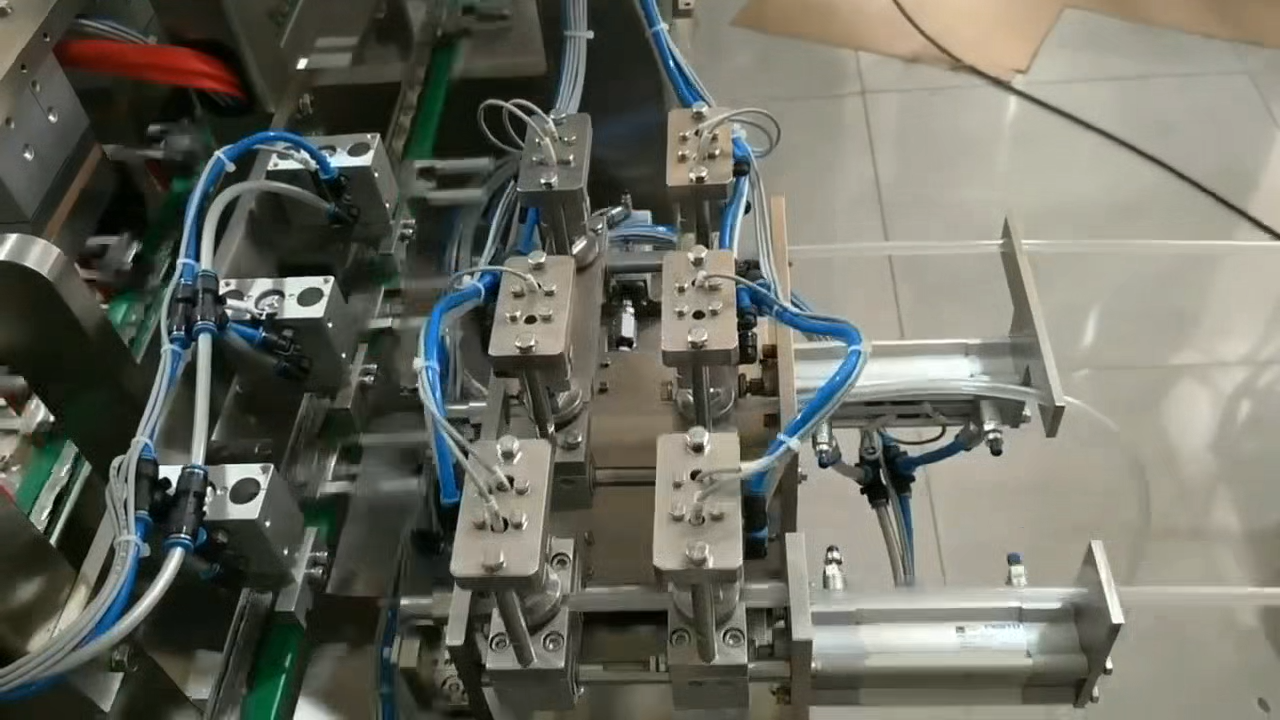

10 | 软管输送工位 Hose transfer station | 具有安装软管卷的支架; Having a bracket for mounting a hose reel; 软管卷在支架上转动平滑、稳定; The hose coil rotates smoothly and stably on the support; 自动定长切割软管; Automatic fixed length cutting hose; 切割刀锋利,切割断膜平整无毛刺; Cutting knife edge, cutting film smooth without burr; 切割刀易于更换; Cutting knife is easy to replace; 分切好的软管自动安装到前车主传动夹具上。 The cut hose is automatically installed on the previous owner's transmission jig. |

11 | 制袋工位 Forming station | 制袋工位具有分膜器,可分开紧密贴合的膜材; The bag Forming station is equipped with a film separator, which can separate tightly fitted film materials. 膜材在分膜器打开的同时,切割好的软管进入两层膜材之间; When the membrane material is opened, the cut hose enters between the two layers of membrane material; 采用气液增力缸一次性完成软袋周边焊接和切割; The gas-liquid booster cylinder is used to complete the welding and cutting around the soft bag. 通过更换模具和夹具变更制袋规格; Changing the bag specification by changing the mold and fixture; 模具加工精度高,保证周边焊接和切割质量; High precision of mold processing, to ensure the quality of welding and cutting around; 模具采用集成式设计,所有模具均由独立的加热器和热传感器, 温度均匀,热补偿快,温控精准; The mold adopts integrated design, all molds by independent heater and heat sensor, uniform temperature, fast heat compensation, precise temperature control; 模具均内嵌切割刀; The mold is embedded with a cutting knife; 模具更换简单,易于调整; Mold replacement is simple, easy to adjust; 袋与袋、组与组之间无废边,减少膜材浪费; There is no waste edge between bag and bag, between group and group to reduce the waste of membrane material; 设备具有过热和温度损失报警; Equipment with overheating and temperature loss alarm; 焊接温度、制袋时间可在触摸屏设置; The welding temperature and bag-Forming time can be set on the touch screen. 模具无需主动冷却。 Molds do not need active cooling. |

12 | 软管焊接工位 Hose welding station | 通过加热模具将软管和软袋可靠焊接在一起; The hose and soft bag are welded together reliably by heating the mold; 模具加工精度高,温控精准,有效防止软管根部渗漏; High precision of mold processing, precise temperature control, effectively prevent leakage of hose root; 焊接温度、时间均可通过触摸屏设定。 The welding temperature and time can be set through the touch screen. |

13 | 输出工位 Output station | 将生产完成的软袋从设备中传递出来。 Transfer the finished soft bag from the equipment. 可定制输送带。(单独报价) Customizable conveyor belt. (Separate quotation) |

14 | 电器柜 Electric cabinet | 设备前方具有一个电器柜; An electrical cabinet is provided in front of the equipment; 电器柜材质SS304,防护等级IP54; Electric cabinet material SS304, protection grade IP54; 电器柜内电路具有保险丝或热电磁保护。 Electrical cabinet circuit with fuse or thermal electromagnetic protection. |

15 | 层流罩 (单独报价) Laminar flow hood (Separate quotation) | 可付费增加层流罩; Can pay to increase the laminar flow hood; 层流罩具有初级过滤器和高效过滤器,将为设备内部提供百级空气环境; The laminar hood has a primary filter and a high efficiency filter, which will provide a 100-level air environment inside the equipment. 层流罩框架和外罩均为304不锈钢制成; The frame and outer cover of the laminar flow cover are made of 304 stainless steel; 层流罩将安装在设备框架上方,覆盖设备所有工位; The laminar flow cover will be installed above the equipment frame to cover all stations of the equipment; 层流罩具有照明灯、紫外线杀菌灯、压差表等; Laminar flow cover with lamp, UV sterilization lamp, differential pressure meter, etc. 层流罩预留PAO检测口。 A PAO detection port is reserved for the laminar flow hood. |

16 | 其他 Others | 可付费增加在线风速、在线尘埃粒子、在线浮游菌检测等功能。 Can pay to add online wind speed, online dust particles, online plankton detection and other functions. |

序号 SN. | 名称 Name | 图片 Pictures | 品牌 Brand | 说明 Description |

1 | PLC |

|

| SIEMENS PLC及相关IO模块采用西门子产品 PLC and related IO module adopts Siemens products |

2 | HMI |

|

| SIEMENS 10寸触摸屏 120inch touch screen |

3 | 伺服电机 Servomotor |

|

| SIEMENS 含西门子伺服控制器 Including Siemens servo controller |

4 | 减速电机 Reduction motor |

|

| SEW |

5 | 气源处理器 Air source processor |

|

| FESTO 含减压阀、过滤排水阀、气源开关、压力传感器及显示表 Including pressure reducing valve, filter drainage valve, air source switch, pressure sensor and display table |

6 | 阀岛 Valve island |

|

| FESTO 含通讯终端 Communication terminal included |

7 | 标准气缸 Standard cylinder |

|

| FESTO 所有规格气缸 Cylinders of all specifications |

8 | 气爪 Air claw |

|

| FESTO |

9 | 气液增力缸 Gas-liquid booster cylinder |

|

| TOX |

10 | 磁性开关 Magnetic switch |

|

| FESTO |

11 | 接近开关 Proximity switch |

|

| IFM |

12 | 编码器 Encoder |

|

| OMRON |

以上图片仅供参考,不作为最终形式确认。 The above pictures are for reference only, not for final confirmation. | ||||

SN. | 名称 Name | 数量 QTY | 单位 UNIT | 型号 SPECIFICATION | 品牌 Brand | 说明 Description |

1 | 软管切刀Tube knife | 8 | 件EA | CSTK | 恒驰Capston | —— |

2 | 膜切刀Knife for film | 2 | 套SET | CSS2MK-100ml | 恒驰Capston | Knife for 100ml |

3 | 膜切刀Knife for film | 2 | 套SET | CSS2MK-250ml | 恒驰Capston | Knife for 250ml |

4 | 膜切刀Knife for film | 2 | 套SET | CSS2MK-500ml | 恒驰Capston | Knife for 500ml |

5 | 膜切刀Knife for film | 2 | 套SET | CSS2MK-1L | 恒驰Capston | Knife for 1L |

6 | 孔刀Hole knife | 16 | 件EA | CSS2MKH | 恒驰Capston | 通用Be current |

7 | 垫刀调整垫 Adjustable pad for knife | 100 | 件EA | 0.02mm | 恒驰Capston | —— |

8 | 垫刀调整垫 Adjustable pad for knife | 100 | 件EA | 0.05mm | 恒驰Capston | —— |

9 | 垫刀调整垫 Adjustable pad for knife | 60 | 件EA | 0.10mm | 恒驰Capston | —— |

10 | 夹具Clamp | 2 | 件EA | —— | 恒驰Capston | —— |

11 | 加热棒Heating rod | 12 | 件EA | 230V/1.2kw/345 | watelong | 制袋模具用 For Bag Forming mold |

12 | 加热棒Heating rod | 4 | 件EA | 230V/150w/100 | Watelong | 焊管模具用 For tube welding mold |

13 | 加热棒Heating rod | 4 | 件EA | 230V/1.2kw/310 | Watelong | 印刷模具用 For Printing mold |

14 | 加热棒Heting rod | 1 | 件EA | 230V/1kw/330 | Watelong | 预热用For Preheat |

15 | 铂电阻PT- resistance | 4 | 件EA | PT-100 | Watelong | 通用Be current |

16 | 印刷胶版Printing silicone pad | 2 | 件EA | CSPSP | 恒驰Capston | —— |

17 | 磁性开关Magnetic switch | 5 | 件EA | SDBT-MSB-1L- PU-K-0.3-M8 | Festo | 通用Be current |

18 | 电感式开关Inductive transducer | 2 | 件EA | IE5338 | IFM | —— |

19 | 传感器线缆Cable for sensor | 2 | 件EA | 2M-M8 | 恒驰Capston | —— |

20 | 固态继电器Solid state relay | 2 | 件EA | —— | Linkfreely | —— |

21 | 气管Air Tube | 10 | 米M | Φ3mm | FESTO | —— |

22 | 气管Air Tube | 10 | 米M | Φ4mm | FESTO | —— |

23 | 气管Air Tube | 10 | 米M | Φ6mm | FESTO | —— |

24 | 气管Air Tube | 10 | 米M | Φ8mm | FESTO | —— |

本表中所列为两年备品备件,在设备发货时随机赠送一套; The above list is two years spare parts, which will be delivered with equipment for free. 本表中所列备品备件主要为易损件,不在质保范围之内,在使用完后需要单独进行采购。 The spare parts in the above list are mostly wear parts, which are not in guarantee period and have to be purchased again after using. 本表供参考,实际以合同约定为准。 This table is for reference only, and the actual agreement in the contract shall prevail. | ||||||

Please visit https://youtu.be/XxBndFqMSeE to see the machine video.