This series of water bath sterilizing cabinet use high temperature circulating water as sterilizing medium to carry on the water spraying sterilizing operation. The equipment has good temperature uniformity and wide range of temperature control (80~126℃), which can be widely used for high and low temperature sterilization.

This series of water bath sterilizing cabinet use high temperature circulating water as sterilizing medium to carry on the water spraying sterilizing operation. The equipment has good temperature uniformity and wide range of temperature control (80~126℃), which can be widely used for high and low temperature sterilization of glass bottles, ampoule, plastic bottles, plastic soft bags and other liquids in the pharmaceutical industry. At the same time, it is also suitable for high and low temperature sterilization of all kinds of sealed liquid and canned food in food industry.The sterilizing medium runs in a relatively closed circulation system during the whole working process. The heating and cooling control of the system is indirectly affected by the external cold (cooling water) and hot (steam) energy through the energy channel of the plate heat exchanger to the internal circulating water, so as to achieve the heating sterilization and cooling operation of sterilized articles.

1.Sterilization control principles

This SG series adopts cyclical water as sterilization heating carrier and carry out water-pouring sterilizing operation for articles.

Filling with circulation water (Pure water) to a preset level.Heating up with circulation water. During heating up a preset differential ballast pressure above the relevant saturated steam pressure is maintained in the chamber by compressed air that prevents damage of the product containers. Sterilization for a preset time under a preset differential ballast pressure with a guaranteed temperature distribution inside the product of ±1℃.Cooling with primary circulation water, which is pumped through the cooling water cooled external heat exchanger and sprayed over the load. During the cooling process a preset differential ballast pressure above the relevant saturated steam pressure or a fixed ballast pressure is maintained in the chamber.

The compressed air overpressure prevents damage of the product containers. Draining of circulation water either completely or to a certain level for further cycles.Depressurizing of chamber to atmospheric pressure(release of door interlock).

According to adopting computers and high-performance devices, it increasingly improves the stability and intelligence of the machine, and makes it more suitable for high-intelligent management system of modern workshops. Meanwhile, refined manufacturing, world-famous configurations and good after service make you more satisfactory.

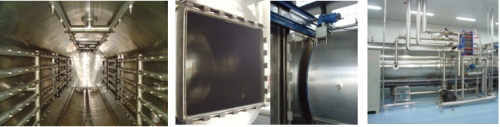

2. Main body (Pic. 1)

The chamber is cylinder and made of SS304, is checked by X-Ray. Its design pressure is 0.245Mpa

According to mechanical and chemical treatment, the chamber surface is bright, beautiful and corrosion resistant.

1 2 3

3. Door structure(Pic. 2)

The autoclave is designed as pass-through (double door) autoclave.The door is sliding type ,the seal is the inflatable type, pressurized with compressed air, and can withstand the chamber temperature and pressure.

● Sterilization cycle can start only after the door is fully closed and locked.

● Supply with instrument-grade compressed air: thanks to the special cross-section, the compression fluid cannot escape toward the sterilization chamber, compromising the sterility of the chamber and of its contents.

Pipe system (Pic.3)

Pipe system is consisted of internal circulation and external circulation. The former is sterilizing medium channel, mainly consisted of circulating pump, board type heat exchanger and internal spray system. The latter is “heating” and “cooling” supply channel, consisted of board type heat exchanger

① pipe connection:connected by flange, the material is SUS304

②Board type heat exchanger: The producer of the exchanger is DL which has large quantity of users and good service. It made by SS316L which is special design for high temperature working condition with high heat efficiency, easy to change the plates, easy clean.

③Circulating pump: The producer of the circulated pump is FFC brand, which working temperature can over 150 ℃. The product is vertical multistage centrifugal pump, which is in low noise, low energy cost, free-maintenance and no leakage. This type product is widely used by national customers and after service net is quite complete.

④Spray system: The spray nozzle is produced by Spray Company, USA, and works in big water flux and wide spray angle. A lot of this type spray distributed in the top and side of the chamber can spray the high temperature water into water fog to every corner of the sterilization chamber. It assures the uniformity of the temperature and rapidly cool down the sterilization chamber and materials when needed.

⑤Control valves: The valves are produced by GEMU Company, Germany. The pneumatic water proof hammer angle valve is fixed in cooling water system that the system can work more smoothly. Other valves are heat resistance angle pneumatic valve which are special for steam (180℃). They are bid directional self-adjustable airproof , big flux with 6 million times working life.

⑥Steam trap: Steam trap is the key to control the steam consumption of super water sterilizer which is float-ball type produced by Spirax.sarco Company, UK.

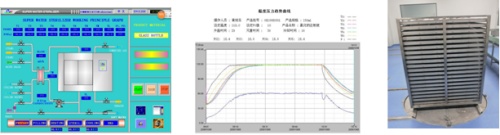

4. Control system (Pic. 4 & 5)

The control system incorporated with: PLC + HMI(Touch screen)+PC computer+A4 printer + Data recorder

●The PLC is SIMENS S7-1215.

●The HMI(Touch screen) is made by SIMENS, SMART700.

●PC Computer monitor software the control system is comply with 21 CFR part 11.

The displaying technologic flow, alarming, historical curve and report printing.Real-time shows the temperature,pressure,time,F0 value,product name,operating member and so on.

All these data and curve can be printed out by A4 printer.

●Data recorder:Paperless Yokogawa data recorder

4 5 6

5. Loading system

Including the Special designed sterilizing cart, automatic in and out cabinet system, 360°turntable and automatic lifter

①Loading cart (Pic. 6)

The material of sterilizing cart is stainless steel.

②Automatic in and out cabinet system (Pic. 7)

The national patent “automatic access to cabinet” is equipped, because of the big chamber which will cause the more inconvenience of in-out cabinet.

The principle of this equipment is that the frequency control motor outside the chamber makes the chain wheel operating, then the chain wheel make the sterilizing cart moving on the drive chains.

③Turntable(Pic. 8)

The turntable is quite flexible. No matter which direction of the sterilizing cart to, the turntable can do it.

④ Hydraulic lifter (Pic. 9)

The lifter can be realized up and down automatically. The sterilizing cart can move up and down on the lifter. We can change the height of lifter to insure the loading and unloading on the same position.

7 8

9

6. Technical parameters and configuration list

Basic technical parameters | |||

Model specification | SG-27 Super water sterilizer | ||

Application | IV solution in soft bag | ||

Main process | Feeding,Pure water into chamber and circulating spraying,Heating, Sterilizing,cooling discharging | ||

Cycle time per batch | About 100 minutes | ||

Bag loading quantity | About 6300 soft blood bags per batch(500ml bags, 130x244x30mm) | ||

Sterilizing mode | Hot water spraying sterilization | ||

Working temperature | 100~121℃ | ||

Design pressure | 0.245Mpa | ||

Overall Dimension(L*W*H) (mm) | 8980*4000*2650 mm | ||

Chamber Dimension(L*D) (mm) | 8500*φ2000 mm | ||

Trolley size(L*W*H) (mm) | 7 pcs/cycle, made of SS304, size:1200*1230*1360mm | ||

Net weight (kg) | 14500kg | ||

Standard of pressure vessel | China standard GB150 pressure vessel | ||

chamber | |||

Material contact with products | Thickness:8mm, SS304 | ||

Heat insulation materials and thickness | Aluminum silicate | ||

Piping System | |||

Circulating water pump | FFC series | FFC | 1 set |

Heat exchanger | M series | DL | 1 set |

Pneumatic valve | 514 series | GEMU | several |

Steam trap | FT | SpiraxSarco | 1 piece |

Safety valve | A28 | Guangyi China | 2 pieces |

solenoid valve | 3V1-06 | AirTAC | several |

Detect in Line and Control System | |||

Temperature sensor | PT100 | JUMO | 9 pieces |

Pressure sensor | MBS-1700 | DANFOSS | |

Touch screen | TP700 | Siemens | 1 piece |

PLC program controller | S7-1200 | Siemens | 1 piece |

Door proximity switch | D4N SERIES | OMRON | 4 pieces |

Door driving motor | 380V,3 phase | Yongkun | 2 set |

Paperless Data Logger | 10 channel | 1 piece | |

PC computer | Win10 system | ADVANTECH | |

A4 Printer | HP | HP | 1 set |

Pressure gauge | YTF-98ZK | BLD,China | 4 pieces |

low-voltage electrical components (such as Air switches, AC contactor and Breaker) | Schneider | Schneider | 1 set |

Verify Monitor Mouth | |||

Temperature validation port mouth | DN50 | SN | 2 pieces |

7. Utility consumption

No. | Item | Requirement | Consumption |

1 | Power | AC380V,50Hz,3 phase 4 wires | 23Kw |

2 | Cooling water | pressure 0.2~0.3Mpa | 17500 Kg/batch |

3 | Plant steam | pressure 0.4~0.6MPa | 1700 Kg/batch |

4 | Compressed air | pressure 0.6~0.8MPa | 32m³/batch |