● Photos of Products:

1. Photos of Machine Detail

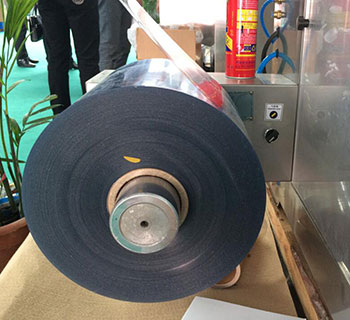

1.1 forming material holder | 1.2forming material connector |

|  |

1.3 picture of photocell register | 1.4 Universal feeder |

|  |

1.5 sealing, embossing and punching station | 1.6 punching mould |

|  |

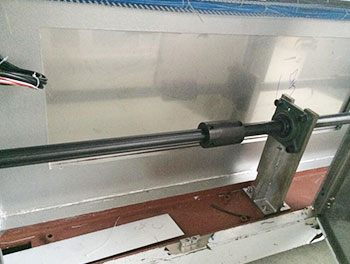

1.7 guider | 1.8 HMI |

|  |

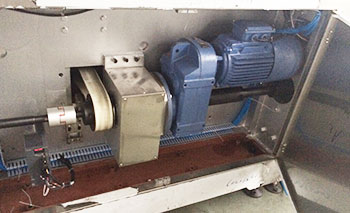

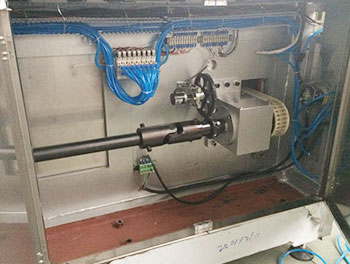

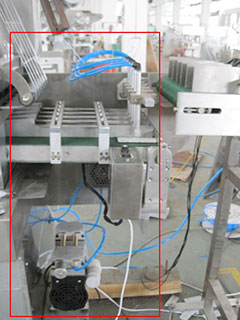

1.9 electrical parts | 1.10 main motor |

|  |

1.11 back side | |

|  |

1.12 picture of camera detector | 1.13 picture of vacuum rejection device |

|  |

1.14 picture of water chiller | 1.15 picture of air compressor |

|  |

1.16 Main Parameters:

| No. | Item | Technical Parameter |

| 1 | Punching times | 10-70 |

| 2 | Capacity | 9600-12000 (standard 80*57) |

| 3 | Max forming Area | 250*110*10(can be special made 250*160*26, while punching speed is less than 25punches/min) |

| 4 | Drive Stoke | 20—120mm(if longer, can be special designed) |

| 5 | Blister Size | 80*57(can be special designed base on customer's requirement) |

| 6 | Air compressor | 0.4-0.8Mpa |

| 7 | Electrical source | 3 phase 380V/220V 50Hz |

| 8 | Total power | 10kw |

| 9 | Main Motor | 2.2Kw |

| 10 | Packing Material | Non-toxicity Hard PVC ( 0.15—0.5×270mm) |

| Gelatinized PTP Alu film (0.02—0.35×270mm) | ||

| Cold forming ALU(0.14-0.2×270mm) | ||

| Dialyzing paper (50—100g×270mm) | ||

| Reel Aperture : 70—76mm | ||

| 11 | Mould Cooling | Tap water or circled water |

| 12 | Overall Dimension | 4000×850×1700(L×W×H) |

| 13 | Weight | 2800kg |

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE