Assembling syringe parts: barrel, needle, top orange cap

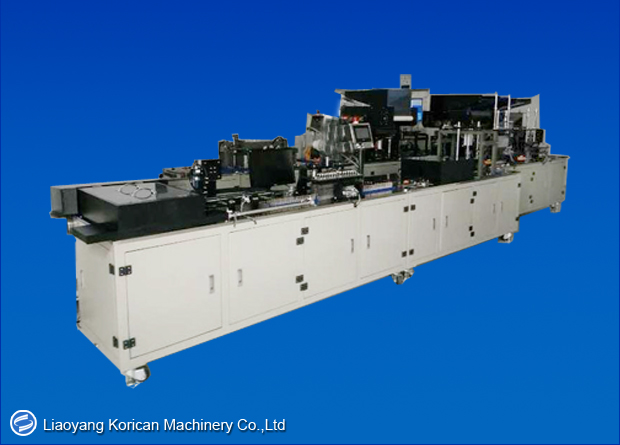

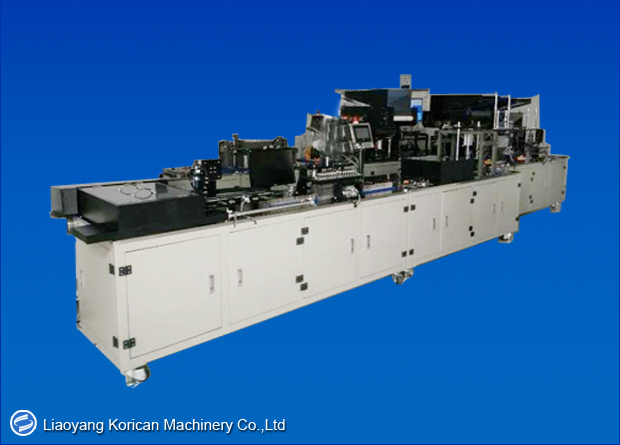

This machine is suitable for assemblying the diabetic syringe.

l Machine Structure and Composition

1.1 Equipment Name: KF-1 Insulin Syringe Needle Assembly Machine

1.2 Assembling Product: barrel, needle, top orange cap.

1.3 The whole machine is including 3 big working stations+drying oven.

1.4 1# working station:

barrel feeding, electric spark (reserved), needle feeding,

waste needle rejection, adhesive dispense, getting into drying oven;

1.5 2#working station:

drying oven outlet, blocking detection, CCD image burr inspection,

CCD image glue inspection, silication, waste rejecting;

1.6 3#working station:

top orange cap feeding, top orange cap pressing,

CCD image inspection, waste rejection, feeding.

1.7 station sequence

1. barrel feeding;

2. needle feeding;

3. waste needle rejection;

4. glue(adhesive) feeding;

5. drying oven; 6. waste rejection;

9. silication;

10. waste rejection;

11. top orange cap feeding;

12. top orange cap pressing;

13. waste top orange cap rejection (3 pcs of CCD camera lens points 120°putting);

14. waste rejection;

15. feeding.

1.8. Key Working Station Introduction

(Function and Technological Process Description)

1. barrel feeding adopts slide rail track vibration add low speed rotary scraper,

guaranteed not to scratch the barrel and feeding in time,

feeding time and quantity can be controlled accurately.

2. needle feeding can be changed with needle clamp, in order to be suitable for

more syringe specifications. The needle feeding method adopts gravity

free falling into the needle hub, it will not cause the secondary damage

of the needle the point burr and other parts of this equipment.

3. The glue(adhesive) feeding adopts dispensing method to make sure the glue is mellow and full.

4. The drying oven adopts ultraviolet ray constant temperature control module,fully drying the adhesive, to make sure firm and reliability.

5. CCD image detection the burrs and back needle and glue,it can judge and memorize the defective products fast and accurately,

the accuracy rate is above more than 99%.

6. block detecting device adopts sensor chip test mode, accurate and efficient,and not to damage the needle point, effectively solve the difficult monitoring

problem during the automatic assembly process.

7. When silication, it comes with the function of big and small air blowing,reduce the silicone oil blocking to zero.

8. The waste rejection adopts air cylinder one-to-one rejecting method to reject every defective products.

9. top orange cap pressing adopts one-to-one method to compress.

l Technical Parameters

2.1 Main Machine Power: 5KW, 380V, 50hz, 3 phases.

clean compressed air pressure: 0.5~0.7Mpa

2.2 overall dimension: 3mx9m (the occupied area is not including the passage)

2.3 working efficiency: about 12000--15000pcs per hour

2.4 assemblying qualification rate: more than 99%

(all the provided assembly parts comply with buyer's drawings

and sample requirements)

2.5 weight: 4T

2.6 every pc of clamp adopts the 34 pcs of products.

2.7 The operators for the assembly machine: 2-3 persons

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE