(With Wash-in-place (WIP) system and Electrical Heating)

(With Wash-in-place (WIP) system and Electrical Heating)

● Samples of Coating Tablets

● Technical Parameters

| Model | BGB - 75D | |

| Production capacity (kg/run) | 75 | |

| Speed-adjusting range of filmcoating drum (rpm) | 4~19 | |

| Motor power of main machine (kW) | 1.1 | |

| Temperature-regulating range of hot air (° C ) | Normal temperature ~ 80 ° C | |

| Filtration accuracy of hot air ( mm) | 0.5 mm (100000 grade) | |

| Motor power of air heater (kW) | 1.1 | |

| Motor power of exhaust machine (kW) | 3 | |

| Motor power of peristaltic pump (kW) | 0.18 | |

| Overall dimension of main machine (mm) | 1350×1010×1630 | |

| Weight of main machine (kg) | 650 | |

| Overall dimension of air heater (mm) | 1100×900×2140 | |

| Weight of air heater (kg) | 400 | |

| Overall dimension of exhaust machine (mm) | 720×780×1950 | |

| Weight of exhaust machine (kg) | 300 | |

| Power supply:3-phase 5 wire | 380V、40A | |

| Clean air | Pressure | >0.6MPa |

| Air consumption | ≤1 m3/min | |

| Water supply | Pressure | >0.15MPa |

| Electrical heating power | 20kw | |

| Material | If not different specified | |

| Product contacted | 316L | |

| AHU filters | F8 polyester fiber | |

| H13 fiber glass | ||

| Product contacted sealing/lubricant | Food Grade | |

| Surfaces finish | If not different specified | |

| Product contacted | Mirror finished Ra ≤ 0.4 µm | |

| Others | Satin finished | |

● Performance

1. The control system consists of PLC and HMI. The design is reasonable and programming is flexible, which are adapt to the different needs of pharmaceutical technology, thus featuring reliable work, stable performance and conforming to the requirement of GMP.

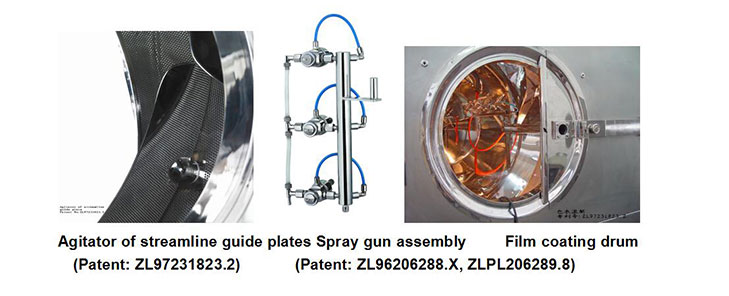

2. Under the action of the agitation of streamline guide plate, the tablet cores are tumbling smoothly and exchanging frequently, thus elimination the phenomenon of tablet cores falling from a high place and the collide, so that solve the problems of broken pieces and chipped edged and also improve the rate of finished products. The narrow surface of the guide plate eliminates the adhesion of coating material on its surface, thus saving the coating material and improving the quality of medicine.

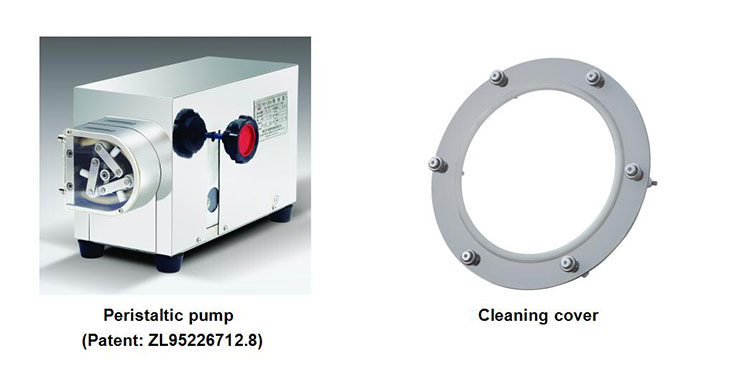

3. The peristaltic pump with constant pressure and variable eliminates the need for a return pipe. The turning radius of the drum varies with the pressure. The slurry output and the quantity of slurry sprayed are balanced from plugging-up, and saving the coating material, moreover the cleaning is simple, without deed corner.

4. The spray gun is specially designed for film coating machine with even atomization and large coverage of spraying. The universal adjustable spray head makes the cleaning mechanism of spray gun unaffected by charge quantity, so that coating can proceed continuously, thus reducing the coating time and saving coating material.

5. Display and control the negative pressure in the coating drum

We have set up a negative pressure detecting point in the upper box of the coating machine and installed a 2300-1kpa pressure differential gauge(made by the USA Dwyer Co) on the operating console, operator can operate the touch screen according to the technological specification(for instance, the negative pressure being 10pa),and control the speed of exhaust fan, so as to control the negative pressure in the drum.

6. Display and control of the speed of heat-supply air

We have set up an air-speed detecting point in the heat-supply air pipe and installed a 2001AV air speed gauge (made by the USA Dwyer Co.) on the operating console, the operator can operate the touch screen according to the technologically specified air speed value (8m/s), so as to control the speed of hot air fan and meet the demand for air supply.

7. Display and control of temperature value

Temperature sensors are installed at the air inlet and outlet of the film coating machine. After the temperature signal is inputted to the PLC and compared with the set value (90), the heat exchange is automatically controlled, thus achieving the control of film coating temperature value.

8. Adjustment and control of sprayed syrup

The spray delivery pipe system has the function of fine adjustment of each spray gun, the syrup flow control valve and the pressing wheel of peristaltic pump in the pipe can change the turning radius according to the tightness of syrup delivery pipe(i.e. the pressure at the delivery pipe orifice), thus ensuring a constant-pressure output of syrup while the flow can be automatically balanced at any time according to the quantity of spraying, thus ensuring that the syrup is at the pressure(for instance 0.08Mpa) defined by the technological parameters, and achieving the automatic control of the quantity of syrup.

9. Adjustment and control of the coverage area of atomized syrup.

The spray gun used in the film coating system is designed originally, the atomizing coverage area can be adjusted in 360°with the spray head by turning the angle of spray head cover according to the charge quantity in the machine, the operation is convenient and easy to control, and it keeps the result of atomization from being impacted by the human factor of operating skill, thereby facilitating the preparation of SOP.

10. The memory and the print function

It is possible to automatically record in real time the relevant technological parameters in the production process and to print out thereof according to the requirement, thus avoiding the possible errors of manual record made by the operator and ensuring the truth and reliability of the original record.

11. With WIP system.

1) Different parts of the main machine are collocated with a number of nozzles for cleaning machine on-line.

2) Configured the independent cleaning liquid booster distribution station to make sure the pressure of cleaning liquid from every spray head get up to 0.6Mpa and wash the coating machine effectively.

3) Configured the cycle cleaning and drainage systems for the cleaning process to choose

4) Under the control of the PLC, can program a number of cleaning procedures

5) Under the control of the PLC, dry the remnant water of each nozzle by compressed air

6) Under the control of the PLC, implement fully automatic washing and drying process

● Photos of Machine Details

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE