KY-ZK Suppository Shell Making Machine

The machine is driven by electricity, gas, controlled by PLC operation, with PVC/PE film as packaging material automatic production suppositories product equipment

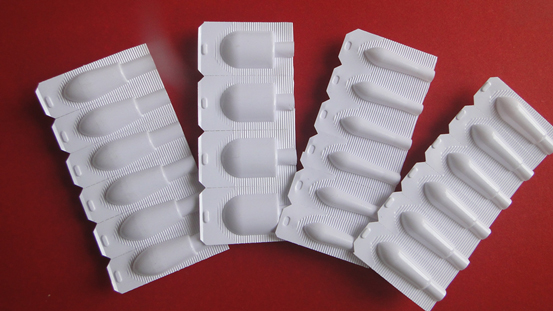

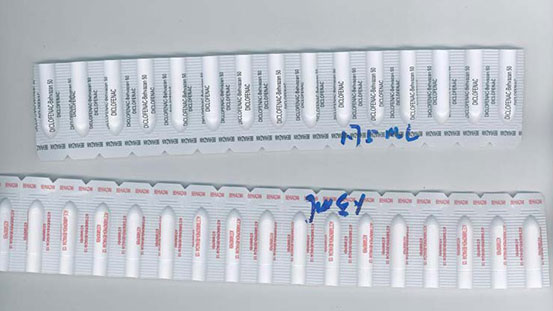

● Samples of Customer's Suppository Shell

● Technical Parameters

| Output | 6500—8000 suppository shells /hour |

| (The actual output is according to your | |

| suppository shell shape and volume) | |

| Single dosage | 0.5—5ml |

| Dosage allowed | <±2% |

| Suppository shape | Bullet, torpedo, duck-mouth. |

| Air pressure | 0.6Mpa |

| Air consumption | 1.5m3 |

| Water quantity | 50kg (Recycling) |

| The voltage of the power | 3PH380V |

| Total power | 3 kw |

| Overall dimension | 2750x1250x1380mm |

| Total weight | 500kg |

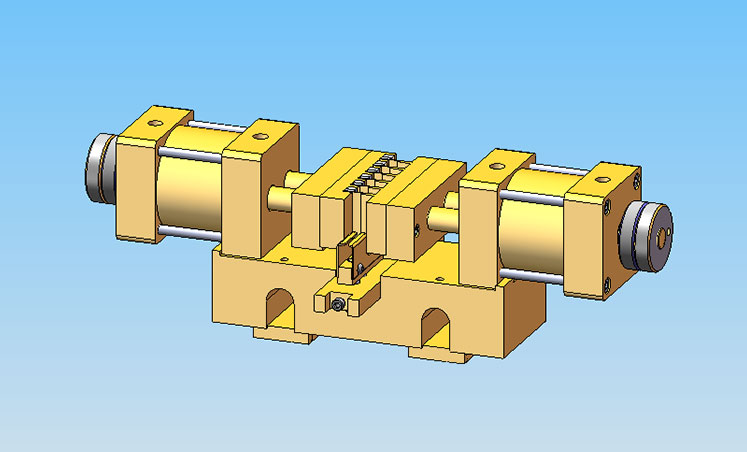

● Machine Description

The machine is driven by electricity, gas, controlled by PLC operation, with PVC/PE film as packaging material automatic production suppositories product equipment

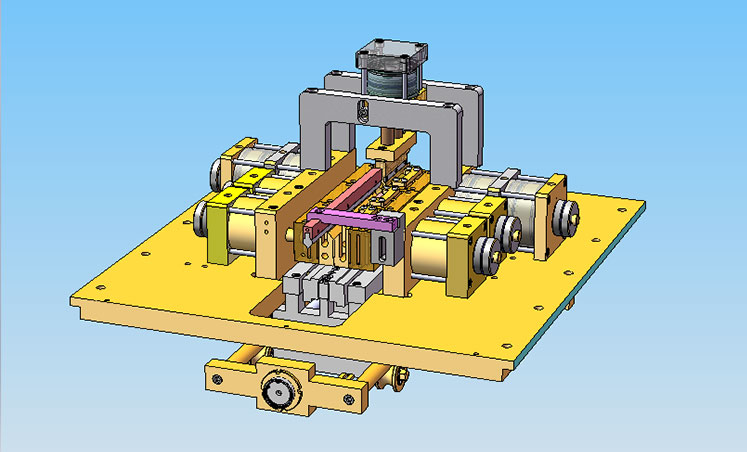

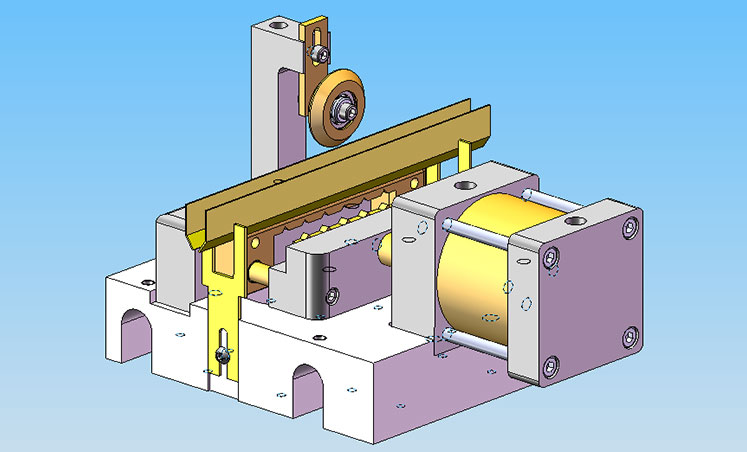

Molding of heat generated by the temperature elements and maintain, molding pressure by multiple groups will be compressed air cylinder converting mechanical energy form.

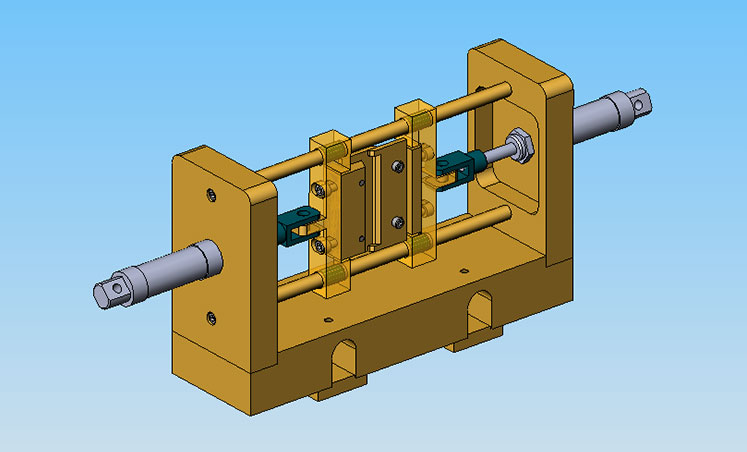

● Working Process

Take-up PVC/PE film through the formation of cavity thermoforming institutions shell, after triangle knife bottom trimming, dotted knife and upper trimming and then by guide import coil plate of finished product volume shell.

This equipment is also with the function of automatic counting, convenient for observation production capacity.

1. Film moulding:

● PVC production

--Smooth preheating mould in first clamp bits

--Located in the second clamp mold heating position

--Molding is located in the third clamp bits

--Docking moulds and molding vertical

2. Trim hem and dotted line cutting

Film materials forming workstation, by cutting knife on underneath figure 6-3), dashed cutting (FIG. 6-4), make it have unified bottom shape and benefit into a single shell.

Figure 6-3 trim hemline schemes

Figure 6-4 dotted line cutting schemes

Section cutting diagram

● The Advantage of Our Machine

1. PLC on-line monitoring function:

This function can breakdown self check alarm and show the cause of the problem,

It is convenient for the operator to do trouble clearing in time.

2. Operation mode:

The machine running in the following way: reset, automatic, manual, emptying.

2.1 Reset:

Machine parts after in the initial position, have to start the machine conditions;

In manual operation or the manual way of molding machines need to be reset after operating

Check the machine connection is correct, and open the main switch

Manual switch in "off"

Press the rest button

2.2 Automatic operating:

Machine is with PLC controller control the operation of the order

Check that the machine connection is correct,

And open the main switch

Install the roller

Press the reset button

Press the start button

2.3 Manual operating:

On a touch screen, click on the "manual" to enter submenu, click on a single function to run.

3. Temperature controller setting:

On the control panel is equipped with the thermostat, each a thermostat control temperature alarm peak (set) according to production needs, if exceed its value

The temperature alarm lights, the machine will stop.

ketchup production line

ketchup production line

Acceptance inspection--Russian Client

Acceptance inspection--Russian Client

2011 FCE

2011 FCE