It is suitable for automatic film packing of soft drawn facial tissues, square tissues, napkins, paper towels, etc.

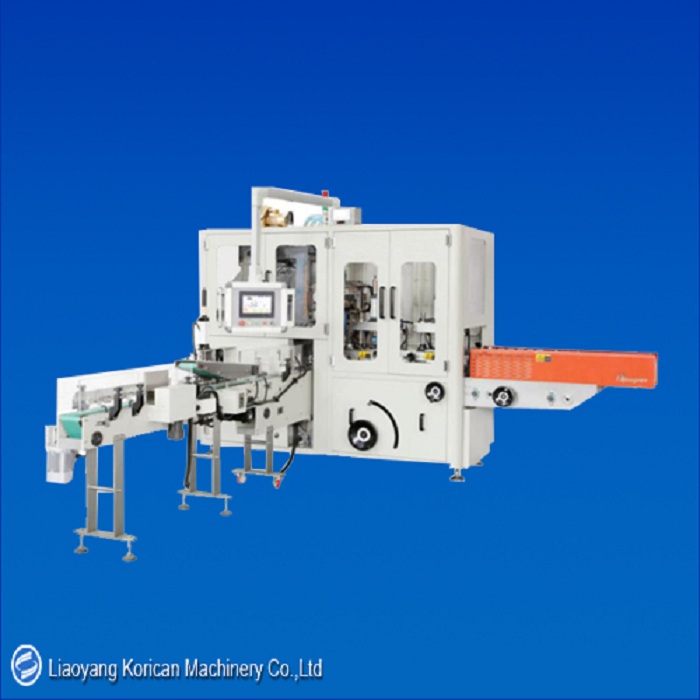

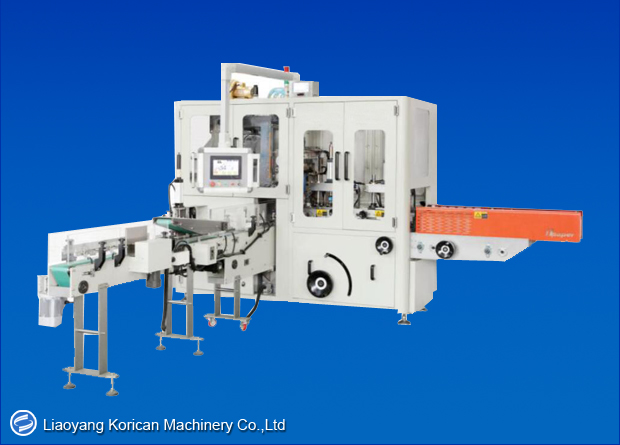

Multi-servo motor, 10’’ touch screen, PLC control system and man-machine interface

display make operation more clear and convenient, with high automation degree, the machine is more user-friendly.

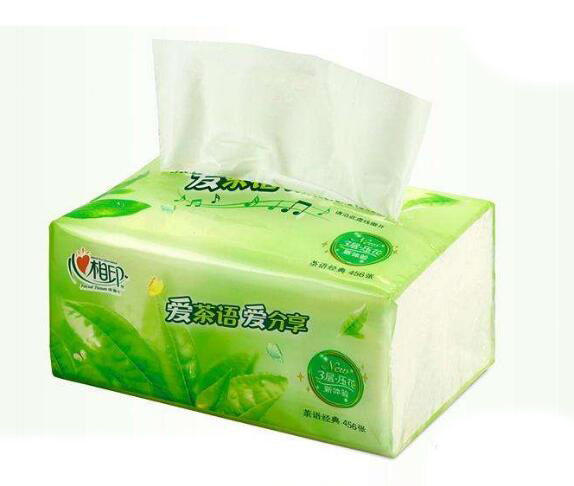

l Samples of Soft Drawn Facial Tissue

l Application Range

It is suitable for automatic film packing of soft drawn facial tissues, square tissues, napkins, paper towels, etc.

l Main Performance and Structural Features

1. Packing forms such as batch No. Printing (optional), tear-line cutting, film feeding, material feeding, wrapping, end sealing, corner folding, side sealing, labeling (optional for dustproof packing), outputting and etc. Featured by compact structure, becautiful packing and film sealing.

2. Multi-servo motor, 10’’ touch screen, PLC control system and man-machine interface

display make operation more clear and convenient, with high automation degree, the machine is more user-friendly.

3. The automatic material arranging and conveying machanism is adopted to facilitate linked production with automatic production line, which can greatly reduce labor cost.

4. The photoelectric eye automatic detection tracking system is adopted, no film movement is made if the bag is empty, so as to save packing materials to the utmost extent.

5. With wide packing range and convenient adjustment, fast switching among various specifications and sizes can be realized.

6. The arc and linear guide rails can be adopted to realize more stable running, lower noise and longer service life.

7. All important parts are provided with linear torque limiter and overload protector to effectively protect machine safety.

8. The machine can be connected with the large orbit paper cutting machine at its front end and with the soft drawn medium packing machine, or case packing line at its rear end.

l Performance Technical Parameters

Item/Model | KPR-90 | |

packaging form | Three-dimensional | |

packing material | CPP, PE, BOPP film, CPP film, PE film, BOPP film, | |

packing specification | L: 130-220mm, W: 80-120mm, H: 20-120mm | |

maximum packing dimensions | L: 220 x W: 120x H: 120mm | |

packing speed | 50-90 bags per min | |

heating power | 7.7 kw | |

total power | 12.00 kw | |

power supply type | 380V, 50hz, 3 phases or according to customer’s requirements | |

air supply | 0.5-0.7 Mpa | |

air consumption | 200-300L/min | |

outline dimensions | main machine | L 4060x W 1260 x H 2300mm |

conveying mechanism | L 3225 x W 480 x H 830 mm | |

machine weight | about 3200kg | |